FAQ

HOW TO CHOOSE THE RIGHT BOAT SIZE?

You got to consider some moments: if you need a tender for your yacht or motorboat, make sure, that you know exactly the maximum sized of tender, which suits for your yacht, and also degree of maximum load of a tender. Boat size is directly depends on maximum power of engine and on maximum load of the boat passengers. If you’re going to use your boat for water-skiing, then there must be an engine with, at least, 25 horsepower in it. In most cases the maximum amount of passengers on boat is specified in the technical specification of the boat, but a number of real seats in boat is different. First you need to decide, which number of passengers you’re want to transport on your boat, and then check what is the real number of seats is in the boat. Look at comparison chart below and find a model that is closest to your needs.

HYPALON или PVC ?

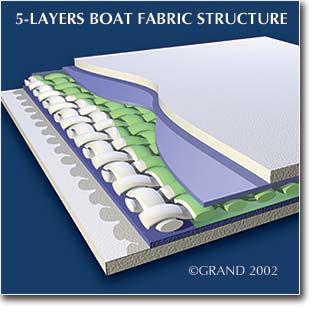

So, let’s first talk about a components for manufacture of inflatable boats. To achieve maximum tightness of cylinders – the main material at manufacturing of high-end inflatable boats is five-layer PVC HEYTEX (German):

• One central inner layer got a 20% part of the total thickness, it serves as an armature and is cloth, made by weaving reinforced fibers.

• Two inner layers cover the fabric base with an airtight, elastic material that makes the fabric airtight and has a high level of adhesion to the fabric base.

• The two outer layers are also made of an air-tight elastic material, which provides wear resistance and material resistance to UV radiation, as well as increases its tightness.

The most popular materials for reinforced fibers are polyester fabric backing with a density of 1100DTEX for ordinary boats and 1680DTEX for professional boats. Elastic airtight materials can be different, and this is the main point of your choice. Currently, there are many different names and trademarks of materials for inflatable boats, but all of them can be divided into TWO large groups: elastomers and thermoplastics.

Elastomers are thermosetting materials, mainly various types of rubber and gum elastic. There are two materials that undoubtedly lead among the elastomers in the manufacture of inflatable boats: HYPALON and NEOPREN. Basically, these materials are used in combination: HYPALON is used, usually, for external coating, NEOPREN – for internal coating. This combination is most common among ordinary boats. HYPALON coating (on both sides) is used only for professional and for some commercial purposes, when the price is less important compared to other material characteristics. One of the main characteristics of such a material is its high operating temperature (up to 140 ° C)

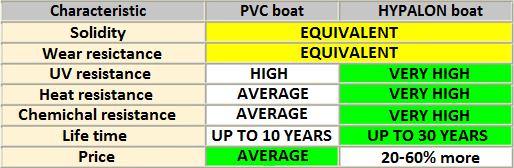

Thus, if we talk about materials for inflatable boats, then you have to choose from HYPALON or PVC. Let’s compare these two materials in the table.

According to the basic parameters of these materials are very similar: modern technologies and the achievements of science in the manufacture of PVC materials reduce these differences step by step. On the practical side, the most important differences are:

• HEAT RESISTANCE. According to this indicator, HYPALON is much more preferable for use in countries with hot climates (equator, subequator, tropics and some sub-tropical countries), where the surface temperature on a boat can reach 80-90 ° C. PVC is also quite popular in these countries, but you need to be more careful with your boat. In countries with an average and cool climate, this difference completely disappears.

• LIFE TIME. PVC is more sensitive to UV radiation than HYPALON. But for today, special chemical additives, which is used in the manufacture of PVC, have practically solved this problem – the 10-year service life of PVC boats is more than enough.

• PRICE. Currently, HYPALON is 5-6 times more expensive than PVC. As a result, a boat made from HYPALON is almost 2 times more expensive than a similar PVC boat for collapsible boats and 40-60% more expensive for RIBs. The difference is more than palpable.

CONCLUSION: Buy a boat from HYPALON if you are going to use it in a hot climate, or if you are looking for a prestigious boat and do not care about its price. In all other cases, a PVC boat is a much preferable option.

FOLDING INFLATABLE BOAT OR INFLATABLE BOAT WITH A HARD FIBERGLASS BOTTOM (RIB)?

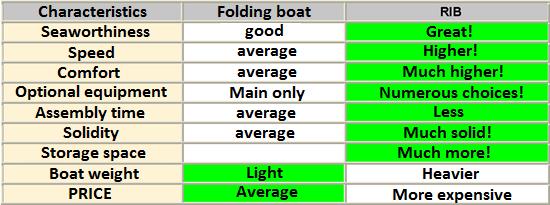

Folding boats are a classic example of inflatable boats, which originate from the first inflatable rowing boats and military rubber boats. Of course, modern inflatable boats are much more improved, due to invention of transom for motors, reinforced bottom plating, V-shaped bottoms and many other remarkable details. Everything is fine, except for one – the bottom. It is still soft! Everything is great, except the bottom. It’s still soft! Sometimes this is a positive factor, but it happens the other way around. A soft bottom allows you to moor at any desert coast without worrying about possible damage – because the bottom of your boat is soft! All inflatable boats are folding and, after blowing off the air, they are easy to transport. Great! But…

But folding inflatable boats can only dream of the features that inflatable boats have with rigid fiberglass bottom (RIBs – RIGID INFLATABLE BOATs). RIB is a combination of an inflatable boat and a traditional one – something in between. RIB is the ability to combine all the advantages of an inflatable boat and a traditional one, excluding all their disadvantages. Pretty successful and very promising achievement.

Let us give an example: The resistance of a soft bottom of a boat that moving through water is greater, than that of any other heavier material, such as metal or plastic, so an inflatable boat is not the best choice for racing. The greatest speed can be reached by boats with a hard bottom. Another point: comfort and a sense of stability of the hard bottom. Folding boats are good for sports and rest, in the case when you do not need anything extra and you need the simplest version of the boat. In the boat with a hard bottom, you will feel complete comfort, it is much better adapted for this.

The next factor: setting-up! If your boat has a hard bottom, you will not need to strain your muscles before each voyage – everything is ready, you just need to pump it up and go!

A hard bottom boat is not just another type of boat, it is a completely different kind of entertainment. In practice, many people become lovers of such boats, once having tried it in use. Of course, such boats are more expensive and heavier, they take up more space and require more care, and this is something to think about.

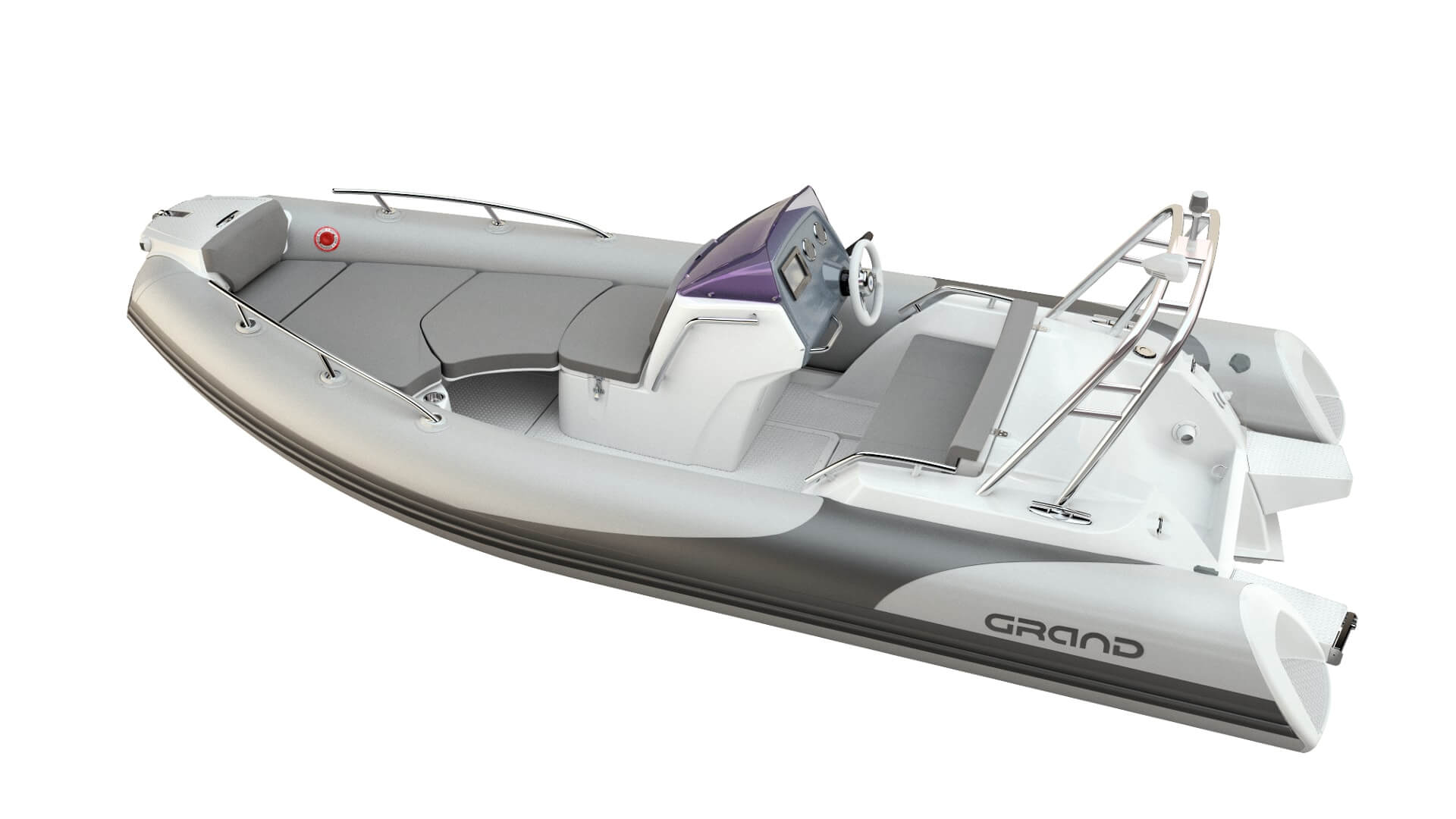

CHOOSE YOUR BOAT GRAND

| GRAND SERIES / models | APPLICATION | |

|---|---|---|

| Silver Line «OPEN» rigid inflatable boat (RIB) Models: S250, S275, S300, S330 Length: 2.50-3.30 m Engine power: 5-25 h.p. Equipped: wooden seats; built-in bow compartment in boats more than 3.7 meters |

|

• It is proposed as a tender for sailing and motor yachts • For fishing • For family swims over short distances (S300, S330) trailer required for transportation |

| Silver Line «OPEN» rigid inflatable boat (RIB) Models: S370N, S420N, S470N Length: 3.70-4.70 m Engine power: 15-60 h.p. Equipped: built-in nose compartment; wooden seats |

|

• It is proposed as a tender for sailing and motor yachts • For sports • For fishing • For family swims over short distances (S300, S330) trailer required for transportation |

| Silver Line «SPORT» rigid inflatable boat (RIB) Models: S300S, S330S Length: 3.00-3.30 m Engine power:10-25 h.p. Equipped: sports center pillar and steering system |

|

• It is proposed as a coaching boat in the junior school for rowing • Alternative to jet ski – can reach excellent speed! • For active walks trailer required for transportation |

| Silver Line «SPORT» rigid inflatable boat (RIB) Models: S370NS, S420NS, S470NS, S520S Length: 3.70-5.20 m Engine power: 25-100 h.p. Equipped: built-in nose compartment; sports center pillar and steering system |

|

• Professional version / used as a rescue boat • Offered as a coaching boat in the junior sport school in rowing and rowing • Alternative to jet ski – can reach excellent speed! • For sports • For diving (S520S – large bow cargo area) • For active walks |

| Silver Line «DELUXE» rigid inflatable boat (RIB) Models: S300L, S330L Length: 3,00-3,30 m Engine power: 10-25 h.p. Equipped: steering rack with steering and a soft double seat with a soft back and storage compartment |

|

• Tender boat for motor yachts |

| Silver Line «DELUXE» rigid inflatable boat (RIB) Models: S370NL, S420NL, S470NL, S520L Length: 3.70-5.20 m Engine power: 20-100 h.p. Equipped: built-in nose compartment with a soft cushion; steering rack with front seat, steering; soft double seat with a soft back and storage compartment |

|

• For fishing • For sports • For diving (S520S – large bow cargo area) • For family swims for short and medium distances trailer required for transportation |

| Golden Line Tenders rigid inflatable boat (RIB) Models: G340EF, G380EF Length: 3.40-3.80 m Engine power:15-40 h.p. Equipped: an anchor pad with a soft cushion; built-in nose compartment with a soft seat; steering rack (in the model G380 with front seat), steering; soft double seat with a soft back and integrated storage compartment; fiberglass tips; built-in fuel tank can be installed |

|

• Offered as a premium tender for motor yachts. • For sports (G380EF) • For family swims for short and medium distances trailer required for transportation |

| Golden Line Riders rigid inflatable boat (RIB) Models: G420, G500 Length: 4.20-5.00 m Engine power: 40-115 h.p. Equipped: anchor plate; built-in nose compartment with a soft seat; steering rack with front seat, steering; fodder wondrous with a soft back and built-in storage compartment; fiberglass tips; built-in fuel system |

|

• Offered as a premium tender for motor yachts. • For active sports (water skiing and wakeboarding) • For diving (G500 – large fore and aft compartment) • For fishing • For family swims for short and medium distances trailer required for transportation |

| Golden Line Cruisers rigid inflatable boat (RIB) Models: G580, G650 Length: 5.80-6.50 m Engine power: 100-200 h.p. Equipped: anchor plate; built-in nose compartment with a soft cushion; steering rack with front seat, steering; U-shaped aft sofa, a removable table and spacious storage compartments; fiberglass tips; built-in fuel system |

|

• Good for travel by a large company. • For active sports (water skiing and wakeboarding) • For swimming long distances trailer required for transportation (2 axles for G650) |

| Golden Line Cruisers rigid inflatable boat (RIB) Models: G750, G850 Length: 7.50-8.50 m Engine power: 200-450 h.p. Equipped: anchor plate; built-in large nose compartment with soft cushions / sande for rest; steering rack with front seat and mini-cabin; double seating with minibar; large storage compartment; built-in fuel system. Optionally: a fridge, a sande for rest, bimini, shower, toilet, etc. |

|

• Premium sea cruise RIB for traveling very long distances • For a large company (up to 12 people) • For active sports (water skiing and wakeboarding) biaxial trailer required for transportation |

PLYWOOD FLOORING, INFLATABLE BOTTOM OR RACK FLOORING?

The folding inflatable boat with a hard flooring (wooden or aluminum) is a traditional inflatable boat. Typically, the flooring consists of several sections (made of special waterproof plywood or aluminum) connected by crosswise lying horizontal aluminum profiles, which serve as a frame.

Rack flooring – one of the simplest options for boat flooring: wooden strips on a flat bottom. This is the simplest option. It does not require a lot of care, but at the same time it is not very solid, since the bottom is flat.

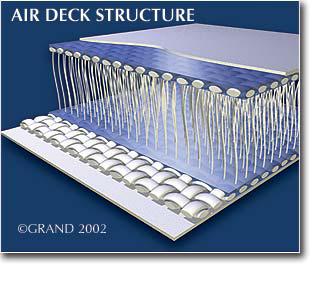

Inflatable bottom is an innovation that appeared only about 10 years ago and quickly became popular. The inner layer of the inflatable bottom, the so-called two-layer fabric or the material with the lowered loops, is a brilliant technical invention, which makes it possible to manufacture a high-tech inflatable bottom. Two hermetic layers of fabric, covered over with resistant PVC (or haipolon) are located at a distance of 40-50 mm from a large number of threads (from 2 to 5 threads per cm2). Being hermetic, this material, when inflated, becomes super-elastic and solid. To inflate it, you need a special high-pressure pump, since the nominal pressure on the inflatable bottom is 4-5 times more than on an inflatable cylinder.

The two most important characteristics of an inflatable bottom are:

Low weight (inflatable bottom on a 3.5 m long boat weighs only 7kg, while plywood flooring on the same boat weighs 24 kg).

• You mustn’t think about the mechanical assembly of the boat, now you only need to inflate it – and it is ready! But, unfortunately, the inflatable bottom has its drawbacks:

• Inflatable bottom is more vulnerable than plywood flooring. With intensive use, it is subject to abrasion, which significantly reduces its durability.

• A boat with an inflatable bottom is 20–30% more expensive.

Conclusion:

• Choose a folding boat with an inflatable bottom in case if you need a lightweight version and you do not want to waste your time assembling the boat. Maximum care and careful use – that’s what you will need in this case!

• Rack flooding is an excellent alternative to the inflatable bottom, as it is also a lightweight handheld option. Such a bottom allows for a much tougher use than an inflatable bottom. Consider this option if you need a small practical vessel and if speed is not main criterion for you.

A boat with plywood flooring is definitely the best choice if you need a boat for various purposes.

ENGINE

In fact, there are three main criteria for selection: brand name (brand), engine and engine leg length. As for the choice of brand, it depends on your personal preferences: your taste, specific market situation, etc. We’re not going to discuss it here. But we will be happy to provide you with information about the engine, as well as the choice of leg length and such important points as engine tilt and balance.

HOW TO CHOOSE THE RIGHT ENGINE?

What engine power is best for your boat? Each boat has the most important characteristic Pmax (maximum power). But this does not mean that you should install the most powerful engine. We would like to clarify the situation and suggest you three most typical choices that you could make:

| Ваш выбор | ECONOMICAL | OPTIMAL | EXTREME |

|---|---|---|---|

| Engine power in % from Max acceptable | 40 – 60% | 60 – 80% | 80 – 100% |

| Safety lever on board | High | Very High | Acceptable |

| Мах speed in % from Max possible | By 60% | By 90% | 100% |

| Petrol consuming | Low | Optimal | The Highest |

Economical choice – engine power is about 60 % from max possible for your boat. It is economical and safety choice. With that engine the boat goes slow with full petrol tank, but if it is light, it can reach 60-70% from max possible speed.

Optimal choice – engine power is about 80 % from max possible. In that case you got: the highest safety level on board, reasonable petrol consuming, almost max. Exploitation level (difference in 10 % from max. is not essential, if you, of course, do not take part in race). It greatly increase exploitation term of your boat. If you choose that engine, the boat manifests itself in the best way. We recommend you to exactly that choice as the best and the most optimal for you!

EXTREME choice – engine power reaches 100% of the maximum possible. With this choice, your boat will work ON THE VERGE OF ALL: safety, wear, etc. This is mainly a racing choice, as well as for those who loves extreme situations, hair fluttering in the wind, and usually takes EVERYTHING from life! This is really a fabulous feeling, but only if you are experienced enough in boat handling. Engine power less than 40%: using a boat with an engine with the power less than 40% of the maximum possible is also possible. But only if exploitation features are not important to you, and you love to enjoy other things. Nature is so beautiful, if not disturbing her very much!

Engine power on the verge of 100%: using the engine with the maximum engine power is illegal and dangerous. Please think twice before making a decision, since your life and the lives of those who are next to you in the boat depends on it. Using the boat with overloaded engine, you lose warranty on it and you may have serious problems with the law.

HOW TO FIND THE RIGHT LEG LENGTH?

Usually suitable leg length is indicated in the instructions attached to your boat. Leg length is standard and may be as follows:

| LEG LENGTH | NECESSARY TRANSOM HEIGHT |

|---|---|

| SHORT leg | 381 mm / 15″ (short) |

| LONG leg | 508 mm / 20″ (long) |

| VERY LONG leg | 635 mm / 25″ (ultralong) |

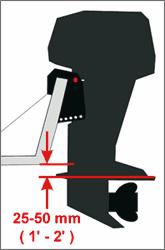

After installing the engine, finally check whether everything is in order: the engine anti-cavitation plate should be located 25-50 mm lower than the lowest transom point.

HOW TO GET THE RIGHT ROTARY SCREW?

A standard propeller is usually attached to each outboard suspension boat engine. Some engine suppliers sell them separately, that means you have a question to the dealer while making a purchase. Without finding out this question, you risk being unpleasantly surprised. In fact, it is almost impossible to give one all-around correct advice on what kind of propeller is needed for your boat, as it depends on many factors. These kind questions are the best to be entrusted to professionals, but if you decide to choose it yourself, then you should proceed as follows:

Install an engine and let him work for 10-12 min, until its power is normalized. Load the boat with the estimated number of passengers and RPM with full throttle at the highest speed. If the maximum number of revolutions is less than needed for your engine – CHANGE THE SCREW ON ANOTHER ONE WITH THE LESS PITCH and check the revolutions again. If the number of revolutions reaches the needed too easy, even not at full throttle, then you should CHOOSE THE SCREW WITH A BIGGER PITCH and again check the revolutions. Try to choose the propeller so as to get the best performance at full throttle, but in any case, do not overload your engine with a too fast propeller (with a large pitch).

For practical reasons, it is better to have at least two propellers for your engine: one for heavy loads (with a small pitch), and the other for lighter option (with a large pitch).

USEFUL ADVICE

HOW TO PUMP UP A BOAT

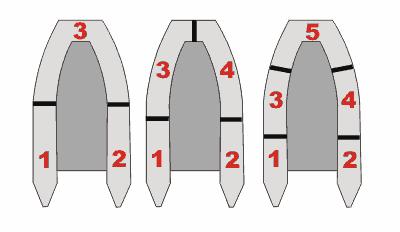

Remember: the boat should be pumped up only after being completely assembled. Each rigid inflatable boat (RIB) can consist of several inflatable parts, such as a multi-chamber cylinder, inflatable bottom, and inflatable keel. It is necessary to observe the following sequence of pumping up: boats with plywood flooring and inflatable keel: CYLINDER => KEEL boats with inflatable bottom and inflatable keel: CYLINDER => BOTTOM => KEEL The cylinder always includes several chambers (compartments) separated by a flexible partition. The sequence of inflating the cylinder is important enough. The main rule: DIRECT FROM THE REAR PART TO THE FRONT – so, first, you need to pump up the rear cameras, then the front ones. For example: remember the only correct way how to inflate a three-chamber cylinder, four-chamber, five-chamber.

It is important to remember: Pump all the cameras up, except the front, until 90% of the nominal pressure is reached. Then go to the inflation of the front camera to achieve the nominal pressure. Since the dividing plates are flexible, while pumping the last frontal chamber to reach the nominal pressure, these partitions will be in a loose state. As a result, the last inflated chamber will trigger an automatic pressure increase in all other chambers to the nominal level. Pay a great attention to the valves being carefully sealed with plugs and tight-fitting after your boat is inflated. Remember that without plugs that are tight to the valves, the required pressure cannot be kept for a long time.

How to adjust the degree of inflation of the boat and its balance?

The task of regulating the degree of pumping up the boat and its balance is quite important for owners of inflatable boats. The reason is simple: the total weight of

The engine, helmsman, passengers, fuel tank and luggage is much more than the weight of the boat. So what about the balance?

The rules are very simple:

Try to distribute the entire load evenly along the boat. Do not allow loads to accumulate in the back of the boat.

Engine – mounted on the transom and it should not be moved.

Helmsman – if you have the engine with tiller control. Helmsman usually is located in the back part of the boat. The best solution is to use a steering panel with a remote system that can be installed in the middle or front part of the boat. If it is not possible, you can use different types of elongated tiller. This solution is not as good as the previous one.

Fuel tank – in some types of engines provides a special place for the fuel tank. But often you can choose it yourself. To balance the front and back parts of the boat, the best position of the tank is in its front. This solution will be good, especially if your boat is empty, and the tank is full. Of course, this is not necessary when the tank is empty.

Passengers – To adjust the balance, place the passengers throughout the boat, evenly and do not allow them to move in it.

Luggage – it should be located only in front of the boat. Do not forget to cover it with some coverlet to protect it from splashing during your swim.

HYDROPLANING AND WAY TO HIDROPLANING.

Speaking about the operation of an inflatable boat, it is necessary to say a few words about the hydroplaning mode and the turning this mode on. What is it? To understand it, you need to understand how the boat moves on the water.

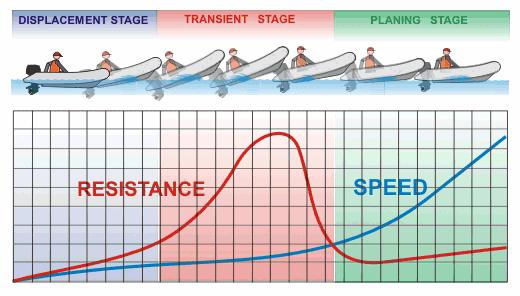

There are three of the most typical modes of boat movement on water: WATER-DISPLACEMENT, TRANSITIONAL MODE, HYDROPLANING. So, let’s try to figure it out.

WATER-PLATING MODE. In that position, it either stands or swims slowly. In this case, the water resistance is small.

Hydroplaning. At this stage, the boat floats with help of hydrodynamic lifting force, which occurs due to the contact of the bottom of the boat with water. At the same time, water resistance is minimal that allows it to reach maximum speed.

TRANSITION MODE. This stage is transitional between displacement and hydroplaning. Have you ever seen a jet takes off? It is something like that. To go through the transitional mode you need to give full gas (or almost full). If your engine is powerful enough, the boat will instantly move away, and its front part will rise up (almost like an airplane). At this moment, water resistance increases to a maximum when the front of the boat is raised, which forms the largest angle with the water (this position is called a jump on the water). And then it seems that the boat is planning on the water and starts moving quickly and easily.

Pay attention to the illustration.

The first picture shows how much engine power is needed to reach different speeds. You clearly see the greatest resistance. After the boat reaches its maximum, it starts gliding. From this point on, it requires less power to keep a given speed. It means that the boat needs more power for a speed of 10 km.ph than for a speed of 15 km.ph. Is it a paradox? No, this is true. In the transitional mode, the contact area of the bottom of the boat with water is larger than while hydroplaning, so, there is more resistance, and more power is required. You see two curves: the green one corresponds to a boat with a good balance or the one that is heavier, and the red one to a boat with a poor balance and one that is lighter. Do you feel the difference?

The second picture shows the change in attack angle as a result of acceleration. The red curve shows a poorly balanced boat or one that is heavier. Green one shows a boat with a good balance or one that is lighter. The phenomenon of “jumps” when going to hydroplaning is well displayed here. It is typical of all planing boats. Unfortunately, this is quite dangerous. In such cases, you risk rolling over. Be careful!!!

Another mistake contributing to this phenomenon is the wrong degree of pumping of the boat and placing a maximum amount of cargo in the back of the boat. To reduce jumps you need to PLACE CARGO IN THE FRONT OF THE BOAT.

The second picture shows the change in attack angle as a result of acceleration. The red curve shows a poorly balanced boat or one that is heavier. Green one shows a boat with a good balance or one that is lighter. The phenomenon of “jumps” when going to hydroplaning is well displayed here. It is typical of all planing boats. Unfortunately, this is quite dangerous. In such cases, you risk rolling over. Be careful!!!

Another mistake contributing to this phenomenon is the wrong degree of pumping of the boat and placing a maximum amount of cargo in the back of the boat. To reduce jumps you need to PLACE CARGO IN THE FRONT OF THE BOAT.

HOW TO CHOOSE NECCESSARY ANGLE OF ENGINE INSTALLATION?

Each boat is very susceptible to the installation angle of the engine leg. If this angle is wrong, the efficiency reduces and your boat becomes more dangerous. Try to find the best option by changing the installation angle: the most stable position of the engine.

A) when the engine is installed too low, the front of the boat goes down, with a lot of splashing.

B) when the engine is installed too high, the front of the boat rises, the hull of the boat practically does not touch the water, equilibrium is lost and the risk of overturning increases. Air gets into the propeller, this leads to the phenomenon of cavitation of the propeller.

C) optimal balancing: the boat goes smoothly, quickly, contacting enough water, with the installed engine leg in an upright position.

PHENOMENON OF AERATION (CAVITATION) OF A SCREW PROPELLER..

The phenomenon of aeration, which is mistakenly confused with “cavitation”, means the ingress of air into the propeller. It increases the number of engine RPM and it becomes higher than normal. You probably know the characteristic sound of the “motor roar” on sharp turns or in other similar situations. Remember that aeration has a harmful effect on the engine and significantly reduces the comfort level of passengers. Here are some causes of aeration:

| REASONS | ELIMINATIONS METHODS: |

|---|---|

| Wrong length of the engine leg/transom or its installation | Check the lowest point of the bottom of the boat (close to the foot of the engine) is at least 25-50 mm higher than the engine anti-cavitation plate. |

| If this distance is less, you will have to install the engine lower, or use an engine with a longer leg. As for aeration, the rule is DEEPER – BETTER | |

| Wrong installation angle of the engine: engine leg is too raised | If the bottom is in a strained state, the flow of water under the rear of the boat is disrupted and this causes aeration. |

| To solve this problem check the bottom whether it is stained. | |

| For it: Inflate the boat cylinder and the keel to the nominal pressure. Check if the flooring is firmly on the bottom or the inflatable bottom. | |

| Folding boats: the bottom is not strained enough | If the bottom is in a strained state, the flow of water under the rear of the boat is disrupted and this causes aeration. |

| To solve this problem check the bottom whether it is stained. | |

| For it: Inflate the boat cylinder and the keel to the nominal pressure. Check if the flooring is firmly on the bottom or the inflatable bottom. | |

| Improperly balanced loading of the boat – the front part is overloaded. | Do not overload the front of the boat. Wrong balancing can also lead to wrong boat movement. |

| Roughness on water | Slow down and pay attention to the balance of the boat. Do not hurry! |

HOW TO TOW YOUR BOAT CORRECTLY?

Of course, you can secure the cable in the usual way by the towing ring at the front of the boat and float. You will not have problems if you need to swim 100 meters. But if you need to overcome a longer distance in the open sea and you will start using a similar method, there is a great chance that when you reach your place, you will not find your towed boat behind you. So how to tow a boat? What is right and what is wrong?

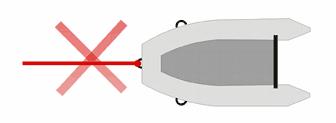

– the simplest towing. This is the worst way possible. It can be used only with a low towing speed (up to 5 km / h), in calm at short distances, under constant control. At high speed, the boat can lose balance and make oscillatory movements, which creates a threat of damaging the rope, the boat itself, or the boat can roll over. Be careful.

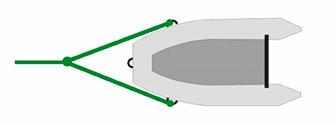

– intensive towing. In that case, the towing cable is attached to the boat through a towing knot or loop, and the cable is fixed on two towing nodes on both sides of the cylinder and can move freely along the eye of the towing cable, as in a bridle. This method completely eliminates the uncontrolled movement of the boat and makes it possible to tow it at maximum speed without problems. We recommend this method as the main one.

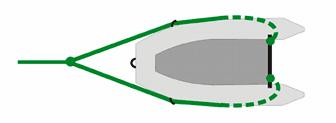

The safest way and the most suitable for towing a boat in a storm. We recommend this method to you, as the most suitable for long journeys on the open sea, when there is no opportunity to find a boat that is towed if it is suddenly lost. According to this method, the ends of the cable are threaded into rings in the front of the boat, pass under the bottom and are set directly on the transom. This is the most durable and reliable way to tow a boat. Even ordinary towing knots are quite strong, but in storm conditions the risk of unexpected jumps increases, which can lead to damage to the towing knots. It is better to use stronger towing knots.

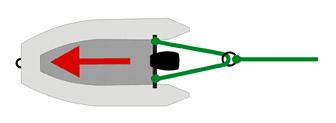

If you had to tow another boat. Fasten the loop, bridles on the transom and connect it to the main towing cable with a metal ring or eyelet, or in another way, so that the main towing cable moves freely along the loop of the bridle. This will allow you to stabilize the moment, especially while changing direction.

SAFETY PRECAUTIONS ON THE BOAT.

Unfortunately, the reason of such hard regulated safety rules on the rigid inflatable boat is a great slew of tragic catastrophes. According to the statistics in oceans, seas, lakes many people have drowned due to their carelessness. As a result, we recommend you: FIRST: YOU MUST PREVENT ALL POSSIBLE HAZARDS WHICH YOU CAN FACE. SECOND: YOU MUST BE READY TO ELIMINATE THEM IF THEY ARE ARRANGED. “To be ready” means to have all necessary safety equipment, to know what to do in the case of danger, strictly follow safety rules. The best way to find out all the rules of safety on water is to attend special courses. We will try to tell you about the most important points.

FITTING OUT THE EQUIPMENT NEEDED FOR OBSERVANCE SAFETY PRECAUTIONS.

Personal Floating Equipment

Personal Floating Equipment must be available on every boat without fail, in accordance with all laws of behavior on the water in any country of the world. There are many different types of these vehicles : swimming vest with support for the neck, inflatable jacket with support for the neck, lightweight jacket without support for the neck, life-saving devices for throwing directly into the water: pillows, rubber rings, horseshoe buoys, inflatable life-saving clothing (vests, pants and so on).

In order to find reliable and legal FSCs, it is better to contact their official distributor and set your requirements for rescue equipment. In any case, FSC must have an official certificate of quality. REMEMBER, YOUR CHANCE TO SURVIVE DEPENDS ON YOUR CHOICE OF RESCUE EQUIPMENT.

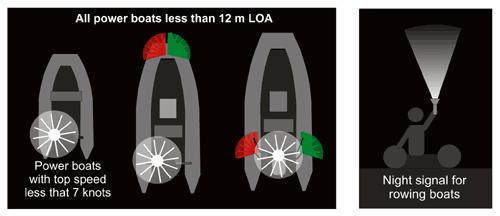

Navigation lights and signaling devices.

Controlling a boat without navigation lights is, firstly, stupid, and secondly, it is against the law. Check the state of your lights and keep them in working condition. Check your local navigation rules so you don’t have any problems with decoding signals. And also check the availability of all necessary permits for signaling equipment, as they are different in different countries. Do not forget about the sound signals, such as: whistles, alarm sirens and visual distress signals (alarm flash, smoke flash or even an ordinary electric lantern) all of which you definitely need to have on board.

TRANSPORTATION AND STORAGING OF BOAT

CORRECT AWNING FOR YOUR BOAT

Having an awning that completely cover your boat is very important for your boat. It protects from rain and dust. But, first of all, it should protect the inflatable cylinder from abrasion and damage – this is its main function. To extend the longevity of your boat, we recommend using a quality awning for it. Usually all manufacturers of inflatable boats supply protective awnings as optional equipment. GRAND can provide awnings for any model of boat: from the smallest to the largest. You also have another possibility – order awnings in any other place, but then you need to consider the following (from our experience): The awning should protect the entire surface of the boat, including cones. It is better to use durable fasteners, rather than rubber rings, eyelet plates, etc., which do not fasten to 100%. This is important in cases when you transport the boat on a trailer on the highway. All edges and corners of the awning should have additional fasteners.

The material from which the tent is made should not pass water, but at the same time it should pass air. It is far from the best option to use a “non-breathing” awning, as this can lead to accumulation of steam, which is harmful for some parts of the boat and internal equipment. As for the color of the awning, you should take into account that the temperature under the direct sunlight increases, and therefore it is better to choose the white color. But then it is not practical at all, as the awning quickly takes on a dirty look. Thus, for a hot climate the best option would be light gray. Pay close attention to the quality of the fabric and the stability of its color. In case of carelessness, your boat can be damaged, without a chance to return it to its original state.

HOW TO CHOOSE A TRAILER FOR A BOAT TRANSPORTATION?

The best way to transport RIBs and even folding boats is to use a trailer. With the right choice of trailer, all operations related with the transportation of boats become simple and safe. How to choose the right trailer? Here are some tips:

The size of the trailer and its carrying capacity must match the size of your boat and its weight. Check your boat’s parameters in instructions. It will be wrong to choose a larger trailer, as you will remember your wrong choice every time you pull out your huge trailer to the beach.

The larger the hull area of the boat and the area of its contact with the trailer, the better. It is better to choose a trailer with a large number of rollers and large longitudinal beams. It is preferable to use longitudinal beams, rather than rollers, since the point of contact between the rollers is much smaller than the beams. You need to adjust the rollers or beams to the shape of the boat. The keel line is the best point of contact and at the same time the strongest in the entire hull. It is better to buy a powerful trailer with powerful springs, large galvanized wheels for use in the coastal area.

After you have selected the desired trailer, here’s a few tips for using it: The boat must be properly inflated. When transporting a boat in a trailer, use a front towing hub for RIBs and side towing hubs for folding boats. Lower the leg of the engine and fasten it on the support column which is provided for this in the trailer. Carefully fasten the boat with straps, use the front, rear and side towing nodes. If you need to transport the boat over long distances, use an awning for it, in order to avoid abrasion and various damage to the container and hull due to the stones and dust which can be found on the road.

HOW TO PACK THE BOAT CORRECTLY FOR ITS FURTHER STORAGING

Sometimes such a procedure as packing the boat can be problematic if you do not know how to do it correctly. Unfortunately, sometimes at first it happens, that after you let the air down and roll up the boat, it becomes larger than its carrying bag. In this case, it is difficult for you to pack the boat in a bag whatever you’ll do. Of course, it depends on your skill, but be sure that after several attempts you will learn how to do it. Follow these rules: Blow the air out of the boat and disconnect all removable parts: flooring, benches, oars (by the way, it’s time to wash your favorite boat); Close the pins with the caps to prevent damage to the cylinder; Create a vacuum in the boat using a pneumatic hose for air bleeding or a foot pump; Fold the transom, press the cylinder to the transom; Fold the cylinder in the boat; Roll up the boat from front part to transom (there may be several bends); Press down the folded boat yourself or lay something heavy on it for 5-10 minutes, so that the remaining air comes out of the boat; Tie a folded boat with a rope or a belt.

If we are talking about a rigid inflatable boat, the recommendations are the same. The only difference is that you need to fold the cylinder into the housing and make sure that the cylinder and the housing aren’t going to be damaged. Also, do not forget to leave the filling valves open when you pack the boat.

BOAT STORAGE ON A WATER

Care of the boat in such conditions is very necessary – at any moment it may rain. At least you should be ready for this. To avoid any surprises, follow a few simple rules: Securely anchor your boat to the pier or to the sea pontoon whenever you leave it in the water;

Learn a few uncomplicated sea knots to secure the boat. This will save your time (there will be no need to put the boat in the shelter every time);

Lift up and secure the engine; If you have the opportunity, be sure to pull the tank and the oars out of the boat; Do not forget to cover the boat with a awning that fit snugly. It is better to use standard awnings for your boat (check the list of accessories for boats);

If you intend to leave the boat in the water under the sun for a long time, you need to slightly reduce the pressure in the cylinder and other inflated parts of the boat. This will reduce the risk of damage to the boat due to increased pressure due to temperature.

BOAT STORAGE INDOORS.

To store the boat, choose a dry, shaded, heated room with a stable temperature. If there is an opportunity, it is better to decompose the boat and inflate it a little. This will be the best way. If this is not possible, we recommend you to check the boat sometime (once every 2-3 months). Do not twist the folded boat: the fewer bends on it, the better. Try to make as little as possible bends on it. Of course, the boat must be clean and dry when you leave it in storage. Try to keep all parts in which water can remain (pillows and other fabric accessories) kept separately in a dry enough place.

STORAGE BOAT DURING WINTER TIME

Of course, the best option is to not leave the boat on the street (can you imagine your favorite boat under the snow). But this is just a tip. And if you still (unfortunately) have no other choice, remember:

– Low temperature. Low temperature does not damage the fabric (the lowest operating temperature of most boats is up to -300 ° C), but there are limitations: as the fabric loses its elasticity at low temperature, there is a problem when moving and folding the boat. In this case, you need to first heat it in the room.

– Awning. For long-term storage is not enough standard awning. It should be larger, with plenty of free space around the boat for ventilation. The size of the awning should allow to cover the entire boat completely, and not just its upper part. Pretty good idea, to make a kind of frame around the boat for an awning, which will look like a canopy – a small house for a boat for the winter.

-Trailer. If the boat is on a trailer, try to install it on any solid and stable base to take the load off the wheels and springs.

-Engine. In winter, you have a great opportunity to give the engine for technical repair to the workshop. In any case, you should not leave the engine in a boat outside in the winter, it is better to remove it.

SAFEKEEPING, MAINTENANCE AND BOAT CARE

Compared with wooden, aluminum or fiberglass boats, inflatable boats require more maintenance. But with proper maintenance and care, you can fully enjoy your boat and its capabilities. In fact, taking care of a boat after you use it is not difficult, but it significantly prolongs its service life. Keep the boat clean and ensure that it is dry during storage. Proper maintenance and repair is the best way to enjoy your boat for a long time.

HOW TO CLEAN AND WASH THE BOAT

It is not difficult at all! The hardest thing is to force yourself to do it. Wash and dry the boat every time you pull it out of the water. After the boat is dismantled, wash it and all its parts with plenty of soapy water.

If the boat is too dirty, use special products to clean it (preferably marked for PVC or for polymer). Do not use solvents, acids, or other chemicals that are not intended for PVC and polymer – it may cause damage to the boat, and such a case is not covered by the warranty.

Use a cotton cloth or sponge to clean the boat to avoid mechanical damage when washing the boat.

You should not make a big effort when cleaning the boat, its material is very susceptible to damage. Always dry the boat after cleaning. The faster the better. If the boat stays wet for a long time (especially in a warm place), its wooden parts, coating, paint, anodized material, etc. can be damaged.

To avoid serious problems with the boat, never dry it in direct sunlight, especially when it is heavily inflated. Blow off the boat before drying, leaving some air in it only to keep it in shape.

CARE OF WOODEN PARTS OF THE BOAT

All wooden parts of inflatable boats are made of special sea plywood or wood that is resistant to the effects of water. All of them are covered with a special marine paint, varnish or laminate. Such paints and coatings are also very resistant to water. When operating the boat on painted and laminated parts, small cracks or scratches may occur. Then the water penetrates to the tree and it begins to swell. If plywood is intended for marine use, you may not worry, because its layers are glued with a special water-repellent glue.

Essentially, damage to paint or laminate is not dangerous for your boat. But if the appearance of your boat and its durability are important to you, it is better, yet, to repair it.

And if you want to do it by yourself:

– Check the condition of all wooden parts at the end of the season. Mark all damaged places.

– Dry all damaged parts in a well-ventilated, dry place.

– Apply to the damaged areas a special marine paint in 2-3 layers. For painting it is better to use two-component polyurethane paints. Since they are the most wear-resistant.

CARE OF METAL PARTS OF THE BOAT

There are three main metals that are used in boats: stainless steel, brass and aluminum. The main disadvantage that affects metal deterioration is corrosion. Stainless steel resists corrosion best and does not require additional coating. For marine purposes use different types of stainless steel alloys. And they all have different degrees of corrosion protection, as well as different prices. For example:

– Alloy 316 (DIN) – or A4: one of the best alloys that will never rust.

– Alloy 304 (DIN) – or A2: after prolonged use it may rust a little, but it is easily removed from the surface with ordinary detergents without the use of abrasives. The price is acceptable.

Brass is also quite well protected from corrosion, but basically all brass parts are nickel-plated or chrome-plated. On the one hand, the brass product acquires a look similar to stainless steel. And on the other hand, it is additionally protected from oxidation (when oxidized, brass become to look dirty and quickly becomes covered with stains). Aluminum is not as resistant to corrosion as stainless steel or brass, therefore, an additional protective layer is required. Most often in such cases an anodized coating is used, which mechanically prevents corrosion. All other methods (painting, varnishing, etc.) are not as effective. You will immediately notice when the anodized coating disappears: the aluminum will look dirty. Unfortunately, if this happens, you have nothing to do. Aluminum anodizing (as well as coating on brass) is carried out only in industrial conditions. So, if the protective coating on the parts has deteriorated, corroded, your best solution would be to replace these parts. Pay close attention to corrosion of electrical equipment. In this case, it is necessary to make sure that different metals do not touch (for example, brass and aluminum), since with such a contact an electrolytic reaction occurs immediately, which has a more harmful effect than ordinary corrosion.

CARE OF PLASTIC AND GLASS FIBER

On an inflatable boat, you can find quite a lot of different plastic components: rowlocks, oar mounts, oar blades, valves, handles, hand rails, etc. They can be made of various plastic materials, such as PVC, polypropylene, polyester, synthetic polymers, and others materials. The main difficulties with plastic are:

– Cracks on the surface, loss of color and turbidity under the influence of UV rays.

– Irreversible deformation of the surface. No types of plastic have a crystalline structure and under prolonged use often undergo plastic deformation.

The content of plastic parts greatly extends their durability, but does not give full protection against damage. Mainly all types of plastics contain special additives that increase the resistance to the destructive effects of UV rays and may slightly delay the aging of plastics. Be careful while choosing chemicals for cleaning plastic, because of improper cleaning plastic can be seriously damaged. If you want to use anything but pure water, make sure that the cleaner you will use is suitable for the type of plastic you are going to clean.

On sale, you can also find so-called “restoration substance” (chemicals) that can temporarily improve the appearance of the plastic. Unfortunately, this action is only temporary. Moreover, you need to be more careful with the restoration substances containing silicone, because:

– The surface coated with silicone, containing restoration or cleaning substances, is much worse glued.

– Very often silicone can be the main cause of seam discrepancy. If it penetrates the junction, the plastic’s ability to stick together is significantly reduced. The best way to prevent such a problem is to protect the boat from the action of UV rays using an awning and reduce the time when the boat is under direct sunlight.

As for glass fiber, the problem here is similar to the previous one. Decorative gel coating, which is provided for all parts of glass fiber, can be polished to obtain a mirror glitter using special polishing substances. Treating glass fiber with such products, you should pay attention to the content of dissolvent and other active chemical elements in them. They can dissolve the gelcoat and damage the shape.

MAINTENANCE OF ELECTRIC EQUIPMENT

For any electrical equipment there is one major problem. It is a corrosion that causes damage. Even considering that most electrical equipment is treated with a corrosion-resistant coating, there are some contacts that are often stained due to oxidation. In salt water, of course, the problem is getting worse. So, maintenance of electrical equipment is not complicated: you need to ensure contacts are as dry as possible. We recommend you to place all the contacts in flexible insulation tubes. Check all cable bases and connections for corrosion. If in the result you identify something, give a clean to this place. Inspect the battery fasteners. Dry, wash and tighten it. Open and wash the navigation lights, check if water does not get into them, and whether the incandescent lamp is working. Replace these lamps every season. If you use usual switches, not automatic ones, then periodically you need to check the appropriate fuses. It would be nice if you also changed them every season.

TIPS ON BOAT REPAIR

Your boat, as any vehicle, needs periodical repair. Lesser you take care of it, more problems it will have. There are great variety of possible damage: from a small perforation to complete destruction. So, each problem requires a special solution. The more serious the failure, the more professional help is needed. Of course, in the case of particularly serious damage, professional repair is required at the service center. But in fact, much of the damage can be repaired in non-professional conditions. Using an inflatable boat, it is very important to know how to fix minor damage, as they can occur at any time, and it is not always convenient to ask a professional. So let’s try to figure out how to do this.

NEESSERY EQUIPMENT FOR REPAIR

If you are going to take a boat trip, you always must have equipment for repair. The most necessary equipment is:

– Shreds of different sizes, in order to put patches on the places, where the boat is damaged (you can take them in the boat repair kit or purchase them separately from your dealer). 10-15 scraps will be enough. Make sure these pieces are made of the same material as the boat (PVC or Hypolon).

– Two-component glue (100 ml), suitable for your type of boat (PVC or Hypolon). Check whether the glue tube is full and securely closed. Carefully read the instruction manual.

– A small plastic container for the preparation of the glue mixture.

– Medium sized brushes (1-2 pieces).

– Small scissors, knife or blade.

– Water repellent sandpaper and masking splicing tape. All this is not difficult to take with you, the main point is not to forget!

FILLING VALVE REPAIR

Damaged filling valve is one of the most typical damage. The problem can be different: the loss of the valve cap, air leakage through the inlet valve, air leakage between the valve itself and the boat cylinder. In most cases, the only way out can be to replacing or reinstallation the valve. You can do this at service stations or independently (in the last point, you will need special equipment to replace the valve). To dismantle the valve, you must: 1. blow off the boat 2. squeeze the valve nut tightly through the boat’s cylinder (maybe even with something mechanical like a vice), but be careful, and do not to damage the container itself. 3. Install the mechanism to fit the valve and unscrew the body from the nut, which should remain inside the vessel’s cylinder.

After dismantling is complete, check whether the valves do not have damage, cracks, and deformations. It is generally better to use a new valve for replacement.

To install the valve, you must: 1. Install the valve nut inside the cylinder or use an old one if it is in good condition (but wash it properly). 2. Put a special marine sealant to seal the valve threads and in those places that are in contact with the cylinder. 3. Screw the valve body into the nut by hand. Then tighten it harder by holding the valve nut through the cylinder (as with dismantling). 4. Leave the valve for 24 hours to stabilize the sealant. 5. Check the seal using soapy water.

ELIMINATION OF AIR LEAKAGE

Air leakage is the main problem faced by inflatable boat owners. Air pressure gives the boat flexibility and reliability, if you lose it, you lose the rest. There are no inflatable boats 100% hermetically sealed! Air leakage occurs in any boat. The question is how much air is lost. How to set it? When the pressure decreases less than 20% per day, your boat is fine, this is an acceptable rate. Such a boat can be without additional inflation for up to 3-5 days. If the pressure loss is more than 20% per day, you should pay great attention to such a leak. That boat becomes soft in less than 1-2 days.

Now the best way to identify the place of air leakage is soapy water. 1. Prepare the mixture: Mix 1: 1 liquid soap and water. 2. Inflate the boat to the maximum acceptable pressure level. 3. Cover the entire surface of the boat with mixture for inspection. If there is a leak, you will immediately find its place: you will notice a trickle of small bubbles. Often the source of air leakage is very small, and it is quite difficult to find it. Use the following search pattern:

FILLING VALVES => SEAL CROSSING ON THE CYLINDER => ALL CROSSED SEAMS => ALL LONGER SEAMS => FABRIC SURFACE.

Explanations: – About 50% of all problems related to air leakage are caused by filling valves, and the main problem is the valves are not closed with a plug, not hard enough tightened, unsuitable or deformed plugs, damaged sealing rings – about 20% of all leaks have a source at the seams – about 30% of leaks occur on the surface of the fabric: various damages (small punctures, cuts) and damages due to abrasion. Ones you have found the source of the air leak, mark it with an indelible marker and clean the surface for repair.

HOW TO GLUE?

A few words about the glue in general. Firstly, the glue you are going to use must be suitable for this purpose. You can purchase it from a boat distributor or in a specialized store. Depending on the type of material your boat, you will need glue for PVC or for HAYPOLON, These are different glues. It is obligatory to make the right choice for your boat and do not forget to read the instructions before you buy glue.

Glue can be one-component or two-component. So what is the difference? Single component glues are mostly multi-purpose. They are easier to use than two-component ones. But the stability of a single-component glues is not so high, especially in hot weather. There is a second component tn two-component glues, it is so-called “hardener”, which stimulates the polymerization of the glue and thereby increases its reliability and thermal stability of the bonding elements.

Our recommendations: – use one-component glue for easy short-term repair, when you do not have the opportunity to repair the damage with two-component glue. – two-component glue is preferable in any case. Use it as basic.

The technology of using glue in case of breakage is quite simple:

1. Locate the damage and select or cut a suitable patch.

2. Prepare the glue mixture: mix the hardener with glue in the required proportion and mix thoroughly. The proportion of hardener is always indicated in the instructions for the glue. Mostly the proportion is about 4-5%, that is, 4-5 parts of hardener per 100 parts of glue. Use the mixture for a maximum of 1 hour, as it dries quickly.

3. Determine the boundaries of the gluing point on the boat with adhesive tape to reduce the consumption of glue.

4. Carefully clean and wash both gluing surfaces. If you have a high poly boat, you definitely need to scrape the gluing surface on the boat and patch with emery paper until the surface becomes completely matte (it is not necessary for PVC).

5. Put the first thin layer of the prepared mixture on both surfaces and dry them for 20-25 minutes.

6. Put a second thin layer of the prepared mixture to both surfaces and dry them for about 5 minutes.

7. Remove the adhesive tape, put a patch on the previously marked place and press.

8. Place the finished product on a hard and flat surface and press the gluing area as hard as possible. Use a metal roller or other cylindrical object (glass bottle, various rollers) for this.

9. Leave the boat for 2 days at rest, without inflating it. If you are doing an urgent repair, leave the boat for at least 2 hours without moving, and then inflate it with minimal pressure. After 2 hours, the seams have 70% strength, which may be enough to reach the your place, if you swim carefully.

PUNCTURES AND SCRATCHES REPAIR

Punctures and scratches may appear because of abrasion or pinching itself. Since it is not a serious damage, you can repair your boat with one patch from the outside. Choosing the right patch size, remember: it must be at least 12-15 mm larger than the damaged surface. That is, the diameter of the patch for puncture should be at least 25 mm. Patches for scratches should have the shape of the scratch itself plus 12-15 mm around.

CUTS REPAIR

Cuts are fairly serious damage. The best way to fix this problem is to stick two patches: one on the inside, the other on the outside. If it is problematic to stick the inner patch, sew the cut with nylon (polyester) and glue only the outer patch. The patch size must be at least 25-40 mm over the cut area. Cut up to 50 mm can be repaired using a standard equipment. If the damage is large, it is better to entrust the repair to professionals from official service centers.

COMPONENTS REPAIR

Use the standard bonding guidelines for gluing boat component parts. Special recommendations are not provided. The only problem is to choose the right parts (seat retainer, lifting and towing units, etc.). We recommend to contact your dealer for clarification.

CYLINDER SEAMS REPAIR

Seams damage is one of the most serious problems. You can repair the seams only in the service centers. In case of unpredictable damage of the seams: Try to put patches on the outside to maintain tightness; Add as much glue as possible, as much as it can harden; Do not inflate the cylinder too much, keep the pressure as low as possible, at which you can pick up a low speed and stay close to the shore; Contact a service center as soon as possible for professional repair.

GLASS FIBER AND GELKOUT REPAIR

If you are the owner of a boat with a rigid fiberglass bottom, there are some words about the fiberglass repair. Technology of fiberglass repair is not difficult, but professional knowledge and skills do not impede. To do this, we recommend you to contact a professional for repairing damaged housing. In the case of non-professional work, you can do more harm.

But, if you still want to try, we will give you some tips. Fiberglass is a combination of two main components: the polymer and the fiberglass itself. For the best appearance, each kind of fiberglass is covered with a decorative outer layer – gelcoat (a kind of polymer). The polymer itself is liquid, but after adding a hardener, it becomes incredibly solid.

There are two popular types of polymer: epoxide and polyester. Polyester is one of the most commonly used materials in the marine industry for producing boat hulls. So, if you have a rigid inflatable boat, 95% that you have polyester. Before the repairs starts, it is very important to know what kind of polymer your boat is made of, since different types do not fit together. Pay attention to this while buying a boat. Fiberglass manufacturers make it of several kinds: glass roving (fiber glass wound into reels), glass fiber mat and glass fabric. Glass roving is used primarily for industrial machines, and glass fiber mat and fiberglass are well suited for routine repairs. A few general recommendations for the most common defects:

Scratches on gelcoat. If the scratches are not deep (up to 0.2 mm), but you worry about the appearance of the boat, you can simply polish it with emery paper (800, 1200, 1500 will be nice) and polish it with a special equipment to a mirror glance. If the scratches are quite deep and the gelcoat layer is significantly damaged, you need to clean the damaged area, put a portion of the gelcoat (you can buy it in any specialized store and from your dealer – do not forget to check the color !!!), and then you need to grind it to a flat surface and polish to a shine.

Cracks in the body and cuts to the body. Such defects are quite difficult to repair, and in this case, special knowledge is required. If you notice cracks or cuts on the body, it is better to ask qualified assistance at a service station for help.